KF bellows refers to the two ends of stainless steel vacuum bellows connected to KF flanges, which are different from ISO bellows and CF bellows. It is the most commonly used one of the three different structural forms of vacuum bellows. Because of its convenient disassembly and assembly, economic benefits, and other characteristics, it is widely preferred by people. It is commonly used in sizes DN50 and below.

KF bellows are machined from thin-walled stainless steel strips with excellent elasticity and flexibility. The excellent mechanical properties endowed by stainless steel allow it to withstand a wide range of pressure and temperature changes without collapsing in a vacuum environment.

At the same time, due to the natural corrosion resistance of stainless steel, our corrugated pipes are not easily damaged by the use environment and circulating medium. Compared with rubber or plastic hoses, it is more durable and less prone to aging and deformation.

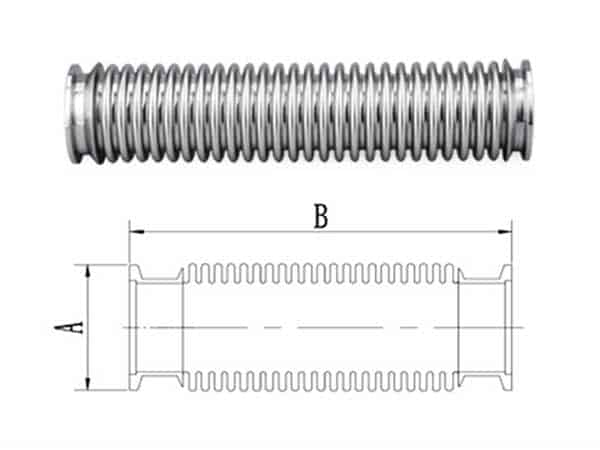

KF Bellows Structure

KF Flange

KF flanges are installed on both ends of the vacuum bellows and are a connection fitting for vacuum pipes. KF flange is a flange made of chamfered back, which is its remarkable shape feature.

There are many different standards for KF flanges, and different companies and organizations may call the same flange differently. KF flange is also called quick-release flange QF, NW, or DN flange. The International Organization for Standardization (ISO), German Standards (DIN), and European Standards (Pneurop) have adopted the name KF.

A sealed vacuum environment is formed by connecting with another matching vacuum flange, and placing a rubber O-ring between them, with the reinforcement of the quick-release clamp.

KF flange has the characteristics of low cost, convenient disassembly and assembly, and reusability.